The crankshaft position sensor is a sensor that tells the computer what position the engine is in. Then the computer knows where to fire the fuel injectors and when to fire the ignition spark plugs.

So when they go bad, the car will often run very poorly. Is it safe to drive with a bad crankshaft position sensor?

Key Takeaway

- It is not safe to drive with a bad crankshaft position sensor because if the crankshaft position sensor is faulty, it can no longer supply the engine control unit with correct information about the position of the crankshaft.

- Not knowing the correct position, the ECU will not know when to fire the fuel injections and the ignition spark plugs and your vehicle won’t start or can stall at any speed.

Is It Safe To Drive With a Bad Crankshaft Position Sensor

No, it is not safe to drive with a bad crankshaft position sensor as it will not inform the engine control unit with information about the rotational speed and position of the crankshaft.

If this part fails or malfunctions, it can disrupt essential engine functions such as fuel injection timing, spark timing, and valve timing.

It may also cause your car to experience hard starts or stalls while driving, poor acceleration, and reduced fuel economy.

All these issues can be dangerous when driving your vehicle and should be addressed immediately by a certified mechanic.

How Long Can You Drive With a Faulty Crankshaft Sensor?

You should drive no more than 100 miles with a faulty crankshaft sensor.

Driving with a faulty crankshaft sensor is not recommended, and it is generally advised to have the issue addressed as soon as possible.

Continuing to drive with a faulty crankshaft sensor can potentially lead to further damage to your engine.

It is best to have the crankshaft sensor repaired or replaced by a qualified mechanic within a reasonable distance, typically no more than 100 miles, to ensure the proper functioning of your vehicle and to avoid any potential complications.

Can I Drive My Car Without a Crankshaft Position Sensor?

No, you cannot drive your car without a functioning crankshaft position sensor. The crankshaft position sensor is an essential component of your vehicle’s engine management system.

It monitors the position and rotational speed of the crankshaft and sends this information to the Engine Control Unit (ECU).

The ECU uses this data to control ignition timing and fuel injection, which are crucial for the engine’s performance.

How Does a Crankshaft Position Sensor Works

The crankshaft position sensor detects the crankshaft position and sends a signal to the ECU. The ECU or the engine control unit calculates the injection timing, ignition timing, and engine RPM according to the crankshaft position sensor signals.

There are three types of crankshaft position sensors:

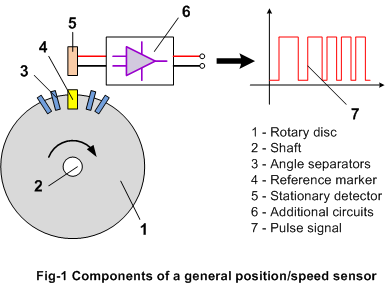

1. Optical Crankshaft Position Sensor

On most vehicles, the optical type is located at the distributor. It consists of LED, photodiode, and rotation slit. It monitors the crankshaft position depending on the slit location.

To check the condition of the optical CPS you need to check the voltage between the sensor power terminal and ground terminal with your ignition turned on. Check if there’s zero or five voltage from the sensor signal wires.

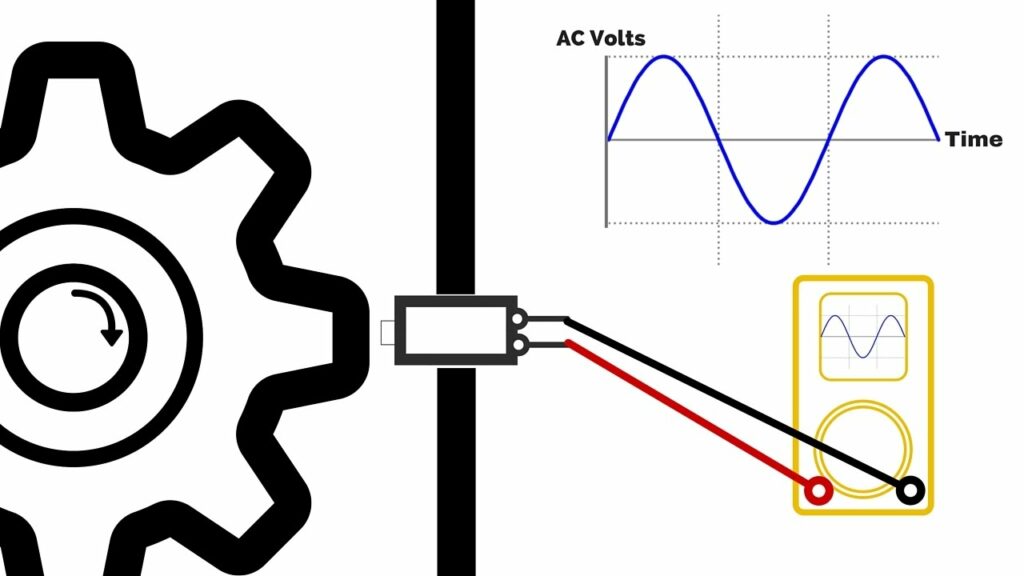

2. Inductive Crankshaft Position Sensor

The inductive crankshaft position sensor consists of a permanent magnet and winding coil. The magnet flux field at the sensor responds as the teeth on the sensing teeth. The sensor generates AC voltage by rotation of the sensing teeth.

The inductive sensor is normally a two-wire device. However, some sensors have three wires, the third being a coaxial shield wire to keep out any interference that may interrupt and corrupt the signal.

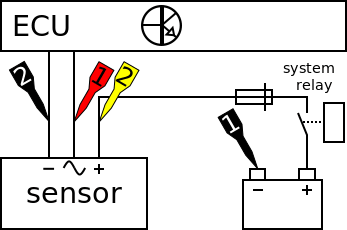

3. Hall IC Crankshaft Position Sensor

The Hall IC crankshaft sensor consists of a Hall element with a semiconductor. When magnet flux to the Hall element changes, the Hall element is activated. It monitors the crankshaft rotation using a Hall effect.

The terminal of this sensor consists of 12-volts sensor power, a 5-volt signal, and ground. Voltages at each terminal should be 12-volts, 5-volts, and 0-volt.

Most Common Signs of a Failing Crankshaft Position Sensor

- Check Engine Light comes on

- Engine Refuses to Start

- Hard Starting and/or Stalling

- Engine Vibration Issues

- Fuel Economy Slippage

- Uneven Acceleration

- Stalling and Backfiring

- Difficulty at low speeds

When a crankshaft position sensor is bad or failing, it will give a series of signs that you can identify and diagnose your vehicle. To be absolutely sure about your diagnostics, you will need a [amazon fields=”B07QZBY49X” value=”thumb”] Here are the 5 most common signs of a failing crankshaft position sensor:

1. Vehicle cannot start

The crankshaft position sensor is part of the timing system. It monitors the speed of the crankshaft and its position. When the piston reaches to top dead center, the crankshaft position sensor sends information to the ECU, and the ECU coordinates with the ignition and fuel injection system.

When the crankshaft position sensor fails, simply due to normal wear and tear, obstructions, or interference it cannot perform its duties. Meaning, a faulty crankshaft position sensor can no longer send accurate information about the position of the piston and the computer will not spray fuel into the engine.

2. Vehicle stalls while driving

When the crankshaft position sensor is failing, it can cause intermittent stalling. The vehicle may stall at all speeds. The ECU will not receive any reliable signal from the crankshaft position sensor, therefore, interfering with the timing system.

At this point, the engine may shut off at any time due to a lost timing signal. Simply, the ECU will no longer spray fuel into the engine and your engine will shut off.

3. No fuel injection pulse

No fuel injection pulse is a sign of a failed crankshaft signal. The crankshaft sensor sends a signal to the ECU and the ECU determines when the fuel injector should spray fuel into the engine and how much.

It’s best if you use a [amazon fields=”B07QZBY49X” value=”thumb”] on your vehicle. The scan tool will tell you exactly what is wrong with your vehicle.

4. No RPM movement while cranking

If the RPM needle on your dashboard is not moving while you are cranking your vehicle, this means there is no crankshaft signal.

This symptom will not apply to all vehicles, but you can combine it with some of the previous symptoms and determine if your crankshaft position sensor is faulty.

5. Engine Vibration Issues

Engine vibration issues can be a sign of a failing crankshaft position sensor due to the critical role this sensor plays in engine operation.

The crankshaft position sensor monitors the position and rotational speed of the crankshaft in your vehicle’s engine. This data is sent to the car’s computer, which uses it to manage engine timing and fuel injection parameters.

When the crankshaft position sensor starts failing, it may send incorrect data to the computer, leading to imbalances in engine timing and fuel-air mixture. This can result in cylinders misfiring, leading to the engine running roughly or vibrating.

6. Fuel Economy Slippage

Fuel economy slippage can be a sign of a failing crankshaft position sensor due to its role in regulating the engine’s fuel injection and ignition timing.

The sensor monitors the position and rotational speed of the crankshaft, sending this information to the vehicle’s computer. The computer uses this data to determine the correct amount of fuel to inject and the right time to ignite the fuel-air mixture in each cylinder.

When the crankshaft position sensor is malfunctioning, it may send incorrect or inconsistent signals to the computer. This can cause the engine to inject too much or too little fuel, or to fire the spark plugs at the wrong time. Both scenarios lead to inefficient combustion, which can significantly decrease fuel economy.

7. Difficulty at low speeds

Difficulty at low speeds can be a sign of a failing crankshaft position sensor due to the sensor’s role in managing the engine’s fuel injection and ignition timing.

The crankshaft position sensor monitors the speed and position of the crankshaft, sending this information to the vehicle’s computer system. This data is used to determine the optimal time for fuel injection and ignition in each cylinder.

8. Backfiring

Backfiring can be a sign of a failing crankshaft position sensor due to the sensor’s crucial role in managing the engine’s timing.

The crankshaft position sensor monitors the speed and position of the crankshaft, which are vital for determining when each cylinder should fire.

This information is relayed to the vehicle’s computer, which adjusts the ignition timing and fuel injection accordingly.

What Causes a Crankshaft Position Sensor To Go Bad

- Electrical or wiring issues: Faulty wiring connections, damaged wires, or electrical problems can lead to a malfunctioning crankshaft position sensor.

- Contamination: The sensor can be affected by oil, dirt, or debris accumulation, which can cause it to fail.

- Wear and tear: Over time, the sensor may experience normal wear and tear, leading to its failure.

- Heat and temperature extremes: Extreme temperatures can impact the performance and lifespan of the sensor.

- Mechanical damage: Physical damage to the sensor, such as from accidents or impacts, can cause it to go bad.

- Manufacturing defects: In some cases, a faulty crankshaft position sensor may be due to manufacturing defects or quality control issues.

- Age and mileage: As a vehicle ages and accumulates mileage, the likelihood of sensor failure increases.

What Happens If You Don’t Fix a Crankshaft Sensor?

If you don’t fix a faulty crankshaft sensor, it can lead to various issues with the engine’s performance and overall functionality.

Here are some potential consequences of not addressing a bad crankshaft sensor:

- Engine misfires: The crankshaft sensor plays a vital role in determining the timing of the fuel injection and spark plug ignition. A malfunctioning sensor may lead to incorrect fuel injection or ignition timing, resulting in engine misfires.

- Rough idle: A faulty crankshaft sensor can cause the engine to idle roughly or inconsistently. This can lead to vibrations and unstable running conditions.

- Poor acceleration and power loss: As the crankshaft sensor helps control the timing of combustion events, a malfunction can negatively impact engine power and acceleration. You may experience reduced throttle response and overall performance.

- Difficulty starting the engine: The crankshaft sensor provides crucial information for the engine to start properly. If it fails, you may encounter difficulties starting the engine or prolonged cranking before it fires up.

- Increased fuel consumption: A malfunctioning crankshaft sensor can disrupt the precise fuel injection timing, causing inefficient combustion. This inefficiency can lead to increased fuel consumption and decreased fuel efficiency.

- Risk of further damage: Ignoring a bad crankshaft sensor can potentially result in additional damage to other engine components. As the sensor’s role is intertwined with critical engine functions, continued use without repair may lead to more severe issues and costly repairs down the line.

How To Replace a Bad Crankshaft Position Sensor

If your check engine light is on and your car is running poorly, there is a good chance that you have a bad crankshaft position sensor.

What the crankshaft position sensor does is tells the ECU the position of the crankshaft. That way the ECU will know when to spray fuel and activate the spark plugs in the combustion chamber.

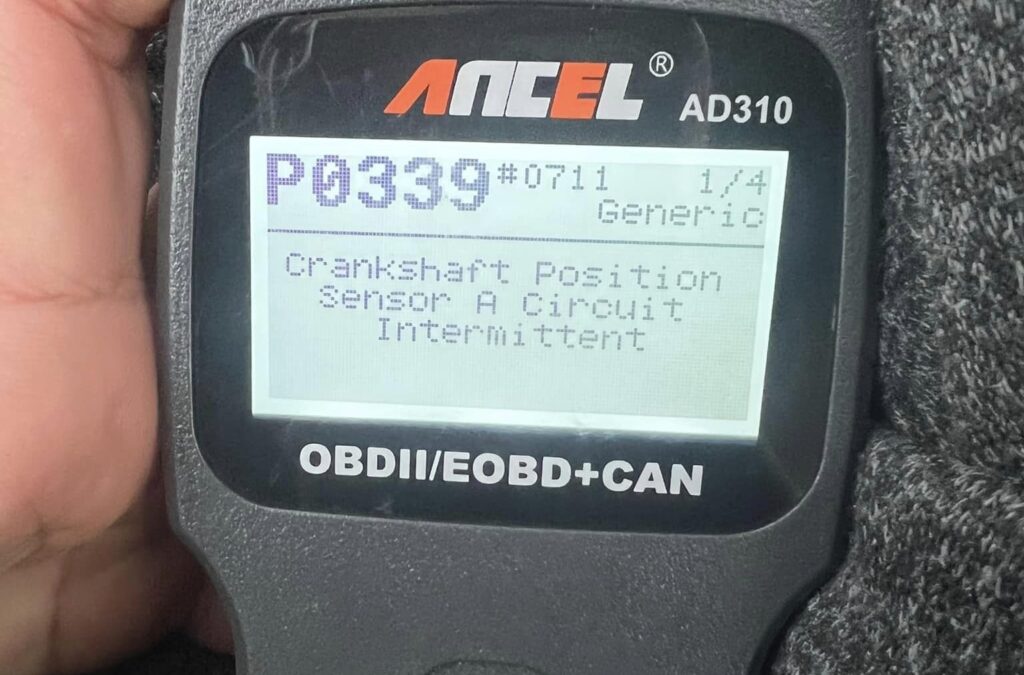

1. Run diagnostics with a scan tool

Hook up a scan tool and run diagnostics on your vehicle just to make sure that you have a bad crankshaft position sensor. The error code for the faulty crankshaft position sensor is P0335. If you don’t have a scan tool, you [amazon fields=”B07QZBY49X” value=”thumb”]

2. Locate the crankshaft position sensor

So now the question comes, where is the crankshaft position sensor located? Most modern cars have the crankshaft position sensor between the engine and the transmission because they measure the flywheel spinning around.

3. Remove the crankshaft position sensor

You will need a little-bitty 10-millimeter socket wrench. There’s not much-working room, so you might need an extension.

4. Install the new crankshaft position sensor

Once you have the old crankshaft position sensor, you can go ahead and install the new one. Just pop it back in the hole and then bolt it back in. You can order a new [amazon fields=”B001TER716″ value=”thumb”].

5. Erase the error code with a scan tool

You have to reset the vehicle computer by erasing the old P0335 error code. Then go ahead and drive your vehicle. The check engine light should turn off at this point. After driving for a couple of miles, you can run diagnostics again just to double-check and make sure everything is alright.

FAQs

Q: What is a crankshaft position sensor?

A: A crankshaft position sensor is a component in the engine that monitors the position and speed of the crankshaft.

Q: What are the symptoms of a bad crankshaft position sensor?

A: The symptoms of a bad crankshaft position sensor can include difficulty starting the car, rough idling, stalling, and a check engine light.

Q: How does a crankshaft position sensor work?

A: A crankshaft position sensor works by using magnetic or optical sensors to monitor the position and speed of the crankshaft. It sends this information to the engine control unit (ECU) to ensure proper fuel injection and ignition timing.

Q: Can a bad crankshaft position sensor cause the check engine light to come on?

A: Yes, a bad crankshaft position sensor can cause the check engine light to come on. The ECU relies on the information from the sensor to optimize engine performance.

Q: What should I do if I suspect a bad crankshaft position sensor?

A: If you suspect a bad crankshaft position sensor, it is recommended to have your vehicle inspected by a mechanic. They can perform diagnostic tests to determine if the sensor is faulty and replace it if necessary.

Q: Can I start the engine with a bad crankshaft position sensor?

A: It may be difficult to start the engine with a bad crankshaft position sensor. The sensor is necessary for the proper timing of fuel injection and ignition, so starting the car may be challenging.

Q: Can I drive my car with a bad crankshaft position sensor?

A: It is not recommended to drive your car with a bad crankshaft position sensor. The sensor plays a crucial role in engine performance, and driving without a properly functioning sensor can lead to further damage.

Q: What happens if a crankshaft position sensor fails?

A: If a crankshaft position sensor fails, it can cause engine performance issues such as stalling, misfiring, and poor fuel efficiency. It is important to have the sensor replaced as soon as possible to avoid further damage.

Q: Can a bad crankshaft position sensor affect the camshaft position sensor?

A: Yes, a bad crankshaft position sensor can affect the camshaft position sensor. Both sensors work together to ensure proper engine timing and performance.

In Conclusion

In conclusion, it’s critical to understand that driving with a bad crankshaft position sensor is not safe or advisable.

The crankshaft position sensor plays a vital role in your vehicle’s engine management system, affecting ignition timing and fuel injection.

If this sensor fails, you could experience a range of issues from poor fuel economy, rough idling, stalling, or even the inability to start your car. Ignoring these signs can lead to further damage and potentially expensive repairs.

Leave a comment