As you replace spark plugs over time, the aluminum threads that secure them become worn. This occurs because spark plugs have metal heads and as you tighten them, it starts pulling threads out of their aluminum heads.

When your spark plug threads become damaged, they are no longer secure and may wobble when you start your engine.

To ensure the proper delivery of sparks into the combustion chamber, here’s how to Helicoil damaged spark plug threads:

- Key Takeaway

- What Are Helicoils?

- How To Helicoil Damaged Spark Plug Threads

- 1. Remove the spark plug wiring

- 2. Make sure the valves are closed

- 3. Access the damage

- 4. Oversize the spark plug hole

- 5. Put grease on the drill bit

- 6. Start drilling the spark plug hole

- 7. Clean the spark plug hole

- 8. Apply anti-seize on the new thread

- 9. Insert the new thread in the spark plug hole

- 10. Clean the spark plug hole

- 11. Select and install the correct insert from the repair kit

- 12. Reinstall the spark plug wiring and start the car

- Is Helicoil a Permanent Fix?

- How Strong Are Helicoil Repairs?

- What Are The Disadvantages of HeliCoils?

- FAQs

- Q: What is a helicoil?

- Q: Why would I need to Helicoil damaged spark plug threads?

- Q: How do I know if I need to Helicoil my spark plug threads?

- Q: Can I Helicoil damaged spark plug threads myself?

- Q: What tools do I need to Helicoil damaged spark plug threads?

- Q: How do I Helicoil damaged spark plug threads?

- Q: Can I Helicoil a stripped spark plug hole in an aluminum cylinder head?

- Q: How long does it take to Helicoil damaged spark plug threads?

- Q: Is there a specific torque specification for helicoid spark plug threads?

- Q: Can I use a Helicoil to repair other types of damaged threads?

- In Conclusion

Key Takeaway

- To helicoil damaged spark plug threads, first tap the hole, screw the helicoil onto the spark plug, apply sealant, and then insert and tighten the new helicoil securely.

- When properly installed, helicoil inserts are considered a permanent fix for repairing stripped or crossed threads on spark plug seats or other applications.

What Are Helicoils?

Helicoils are coiled-wire thread repair inserts used to create internal screw threads that can accommodate standard-sized fasteners.

These inserts serve as threaded bushings or inserts that are inserted into a surface to establish a threaded hole.

Once installed, helicoils provide the correct threads for original fasteners, thus allowing for secure and reliable connections.

How To Helicoil Damaged Spark Plug Threads

Here is how to Helicoil damaged spark plug threads:

1. Remove the spark plug wiring

To access your spark plugs, you will first have to remove the valve cover, any spark plug wiring that might be blocking access, and finally the spark plugs themselves.

What you must remove to access your spark plugs depends on your engine. Newer engines typically feature plastic covers, while older models might not.

2. Make sure the valves are closed

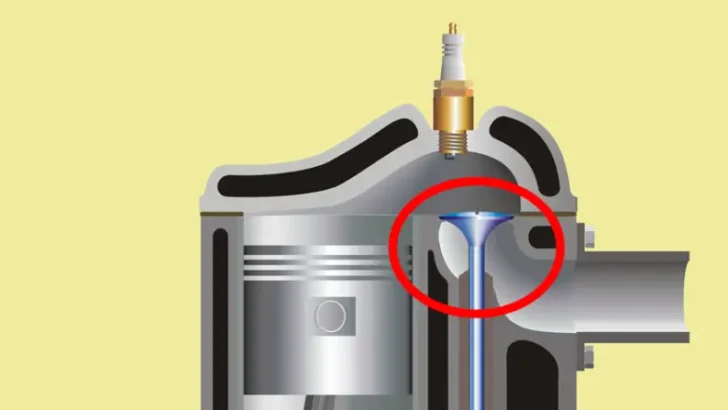

Before you begin to repair the threads on spark plugs, make sure all valves inside the cylinder are closed. Otherwise, when working on damaged spark plug threads, metal shavings could fall down into the cylinder and contaminate everything. This step is essential to avoid this situation.

When the crankshaft rotates, valves open and close precisely at the right time. You must rotate your drive chain until all valves have been closed – this part can be difficult, but be sure not to let metal shavings enter your cylinder!

3. Access the damage

In this step, you have exposed spark plug threads and must assess any damage. Remove all spark plugs that might have a damaged thread and assess the overall situation.

When I start vacuuming a spark plug hole, there is often metal scrape all over it due to broken threads. With a flashlight in hand, I quickly assess the situation and make sure all valves are closed so no metal shavings fall into the cylinder and cause other issues.

4. Oversize the spark plug hole

The Helicoil spark plug repair kit (see the price on amazon.com) will come with a sleeve that you will have to put inside the spark plug hole. You will have to drill the spark plug hole big enough so that the sleeve from the repair kit can fit in.

5. Put grease on the drill bit

Here’s a pro tip that will make your life simpler: before beginning drilling, grease the drill bit with grease. This will catch all metal shavings that come off during drilling and ensure none fall into the cylinder.

To select the proper drill bit for drilling a spark plug hole, take into account the size of wire your car uses and opt for a slightly larger drill bit – usually #80 or #70.

6. Start drilling the spark plug hole

Drill the spark plug hole with confidence. Do not try to force it, as that could lead to issues later. Drill slowly and notice how the grease on your drill is catching a lot of metal scraping – this means you can go ahead and add more grease if needed.

7. Clean the spark plug hole

The grease on your drill bit should trap most metal scraping, but some may still remain inside. To clean out this spark plug hole without letting them fall back down into the cylinder, take a screwdriver and carefully scrape away any leftover metal shavings with it.

8. Apply anti-seize on the new thread

Before you begin thread cutting, be sure to apply anti-seize on the new thread. As metal joins aluminum in an engine block, without proper care the thread could seize up. Furthermore, anti-seize helps catch any metal scraping as you thread the needle in place.

9. Insert the new thread in the spark plug hole

Insert the new thread from the Helicoil repair kit into the spark plug hole and gently hit it with a hammer until it is secured. Once the new thread is secured, get a wrench and start tapping.

The tapping process should not be forced and you have to be careful not to overdo it and damage the cylinder. Go slowly and you will feel when there is no more room to go. At this point, you should have a new thread made in the spark plug hole.

10. Clean the spark plug hole

As soon as you are done installing the new insert in the spark plug hole, blow out the hole and make sure that all metal scraping residue is out. Then, you will need to remove all of the anti-seize.

It is essential to clean all anti-seize from your machine before applying Loctite, as mixing them will cause irreparable damage. Loctite will ensure that the new insert installed in the next step remains securely in place.

11. Select and install the correct insert from the repair kit

Once you select the correct insert size for your spark plugs, apply Loctite. It is essential that the new insert stays secure when taking out the spark plug.

Insert the new insert into the spark plug hole and use a spark plug to push it all the way down. Use a spark plug wrench to tighten it securely; you can check if you are all the way down by taking out the plug – tapping should become harder as you near the bottom. Leave the spark plug there for 10 minutes to cool.

12. Reinstall the spark plug wiring and start the car

Once 10 minutes have passed and the spark plug insert has settled down, it’s time to reinstall the spark plug wiring, valve cover, and any other wiring that you had to remove in order to gain access to the spark plugs.

At this point, you should have new spark plug threads and your vehicle should start running properly.

Is Helicoil a Permanent Fix?

Yes, when properly installed, helicoil inserts are considered a permanent fix for repairing stripped or crossed threads on spark plug seats or other applications.

Helicoils create a stronger thread than the original material and do not back out or sustain damage easily. They provide a durable and long-lasting repair solution.

How Strong Are Helicoil Repairs?

Helicoil repairs are known to provide strong and reliable thread reinforcement. When properly installed, helicoil inserts have equivalent strength to a virgin tapped hole.

The wire thread insert used in helicoil repairs is made of high-quality materials like stainless steel, which offers durability and long-lasting performance.

The Helicoil creates a stronger thread than the original material, providing a robust and secure repair solution.

Overall, helicoil repairs are considered to be highly effective in restoring stripped or damaged threads with substantial strength and reliability.

What Are The Disadvantages of HeliCoils?

- Requires drilling and tapping of the hole to accommodate the helicoil insert.

- The installation process can be time-consuming and complex, requiring precision and attention to detail.

- In some cases, may require special tools for installation.

- If not installed properly, helicoils may not provide the desired level of strength and can fail prematurely.

- Helicoil inserts may dislodge or back out if subjected to excessive vibration or torque.

- Removal of the helicoil insert can be difficult and may cause damage to the surrounding material.

- Depending on the application, Helicoil repairs may not be suitable for high-temperature or corrosive environments.

- Helicoils are relatively expensive compared to other thread repair methods.

FAQs

Q: What is a helicoil?

A: A helicoil is a type of threaded insert that is used to repair damaged threads in a hole. It is commonly used to repair stripped threads in a spark plug hole says Quora.

Q: Why would I need to Helicoil damaged spark plug threads?

A: If the threads in your spark plug hole are damaged or stripped, it can cause the spark plug to become loose or not fit properly. This can lead to poor engine performance and can even cause damage to the cylinder head. Helicoiling the damaged threads can provide a secure and properly threaded hole for the spark plug.

Q: How do I know if I need to Helicoil my spark plug threads?

A: If you notice that your spark plug is becoming loose or if it is difficult to thread it into the spark plug hole, you may need to Helicoil your spark plug threads. Additionally, if you see any signs of damage or stripping on the spark plug threads or in the spark plug hole, it is a good idea to Helicoil the damaged threads.

Q: Can I Helicoil damaged spark plug threads myself?

A: Helicoiling damaged spark plug threads requires a certain level of mechanical skill and knowledge. It is recommended to consult a professional mechanic for this type of repair. They have the necessary tools and experience to properly Helicoil the damaged threads and ensure a secure repair.

Q: What tools do I need to Helicoil damaged spark plug threads?

A: To helicoil damaged spark plug threads, you will need a helicoil repair kit. This typically includes the necessary helicoil inserts, a tap, and a coil installation tool. Additionally, you may need other tools such as a ratchet, socket set, and thread chasers to properly complete the repair.

Q: How do I Helicoil damaged spark plug threads?

A: The process of helicoiling damaged spark plug threads involves tapping the hole to create new threads, inserting the helicoil insert, and then installing the coil with a coil installation tool. This creates new, properly threaded spark plug threads in the hole. It is important to follow the specific instructions provided with your helicoil repair kit for the proper steps to Helicoil the damaged threads.

Q: Can I Helicoil a stripped spark plug hole in an aluminum cylinder head?

A: Yes, it is possible to Helicoil a stripped spark plug hole in an aluminum cylinder head. However, it is important to use caution and follow the proper procedures to avoid any further damage to the cylinder head. It is highly recommended to consult a professional mechanic with experience in repairing stripped spark plug holes in aluminum cylinder heads.

Q: How long does it take to Helicoil damaged spark plug threads?

A: The time it takes to Helicoil damaged spark plug threads can vary depending on the extent of the damage and the skill level of the person performing the repair. On average, it can take anywhere from 1 to 2 hours to complete the helicoil repair.

Q: Is there a specific torque specification for helicoid spark plug threads?

A: Yes, it is important to follow the torque specifications provided for your specific engine and spark plug. Over-tightening or under-tightening the spark plug can affect engine performance and can even cause damage. It is best to consult the manufacturer’s recommendations or a professional mechanic for the proper torque specification.

Q: Can I use a Helicoil to repair other types of damaged threads?

A: Yes, helicoids can be used to repair other types of damaged threads in addition to spark plug threads. They are commonly used in automotive and mechanical applications to repair stripped or damaged threads in various types of holes.

In Conclusion

In conclusion, spark plug repair is a common maintenance task that can be done by any at-home DIY enthusiast if they have the right tools and knowledge.

Helicoil is an effective way to repair damaged threads in spark plugs and restore their functionality.