Is your car suspension making a squeaky or creaking noise while driving down the road, or does your car squeak when rocked? I am going to show you how to fix a squeaky suspension.

Older model vehicles used to have grease fittings on the suspension and once your car started to squeak, you could just fill the grease fittings with a grease gun and the squeaking will go away.

But, modern vehicles do not have grease fittings. Instead, modern vehicles have rubber bushings that get old and start squeaking and creaking while you drive over bumps, rock the car, or when you get out of the car.

One way to fix a squeaking or creaking suspension is to replace the whole suspension system. But, changing multiple parts on your suspension system will cost a lot. Instead, there is an easy way how to fix a squeaky suspension.

Key Takeaway

- To fix a squeaky suspension, you can try lubricating the suspension components, replacing worn-out parts, ensuring proper alignment and installation, and addressing any potential underlying issues.

- A car suspension works by using a combination of springs, shocks, and control arms to absorb bumps, maintain tire contact with the road, and provide a smooth and stable ride.

How Does Car Suspension Work?

Car suspension systems work by utilizing various components to absorb and dampen the impact of road irregularities.

One of the key components is the shock absorbers, which operate in two cycles – compression and extension.

During the compression cycle, the piston moves downward to absorb the energy from bumps and dips on the road.

In an independent suspension setup, each wheel is attached separately to the car body, allowing it to move independently of the others.

This design helps maximize the amount of friction between the tires and the road, resulting in a smoother and more comfortable ride.

How To Fix a Squeaky Suspension

- Locate where the noise is coming from

- Jack up your car

- Remove the wheel

- Locate the bad bushings

- Spray the bushings with lubricant

- Reassemble the wheel

1. Locate where the noise is coming from

Each wheel of the vehicle is supported by a suspension system. Even though behind each wheel there is a suspension system with bushings that can go bad, not all bushings will go bad at the same time.

It is important that you fix the bushings that are bad and not waste material on the good bushings. So, in order to locate where the noise is coming from you will have to perform a small test.

You might not be able to hear the squeaking or creaking noise coming from the suspension system when you drive or go over a bump. So, park your vehicle and start rocking it above each wheel. If you hear a squeaking or creaking noise coming from a particular wheel, that wheel has a suspension with bad bushings.

2. Jack up your car

Once you locate where the squeaking or creaking noise is coming from, jack up your car. If you don’t have a jack, you can grab one on amazon.com. After you jack up your car, place it on jack stands for maximum safety.

The last thing you want is for your car to fall down while you are working on it or under it. Each vehicle has different jacking points, but the ones on the image provided are the most common jack points.

3. Remove the wheel

With your vehicle placed on jack stands, remove the wheel. You can remove the wheel by removing the bolts. Each vehicle has a different number of bolts, but the number of bolts is usually five.

If some of the bolts are rusted and won’t come off, spray some WD40 on them and let them soak for a couple of minutes before starting again.

With the wheel removed, you have exposed the suspension system and the bushings that are bad. Make sure to store the bolts and don’t lose them because you will need them in a couple of minutes to reinstall the wheel.

4. Locate the bad bushings

The bushings are part of the suspension system and are made of rubber. They act as a vibration isolator with the purpose to prevent metal-to-metal contact between the other parts of the suspension while driving the car.

Even though they are made out of hard rubber, they still allow some movement which is very important. Every time you drive your vehicle, the bushings are moving and are constantly exposed to the elements underneath the vehicle.

Being under so much exposure, they are doomed to fail. You will be able to locate the rubber bushings behind each wheel as shown in the photo.

5. Spray the bushings with the lubricant

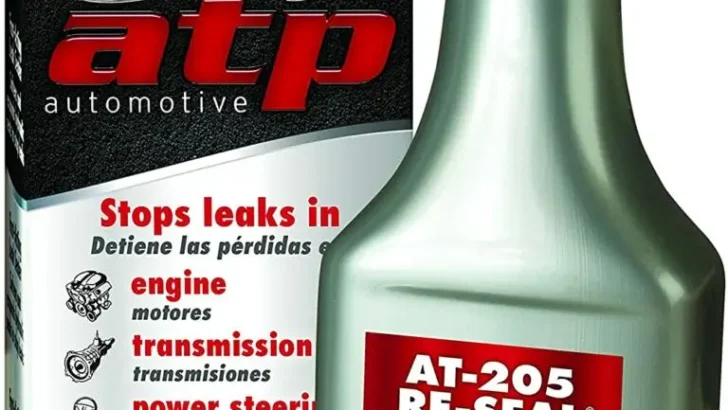

The bushing lubricant that I use is called AT-205 Re-Seal and you can grab it on amazon.com. It is a clear polymer liquid that rejuvenates rubber bushings. Pour the lubricant into a spray bottle and spray it on all the bad rubber bushings. Make sure to get enough of the product on the bushings and make them soaking wet.

You need to spray the torsion arm bushing, frame bushings, and strut mount bushings. Basically, every part of the suspension that is made out of rubber can be sprayed with this lubricant.

This will take care of the squeaking and creaking noise coming from the suspension. You could spray WD40 as well, but it will wash off with the first car wash or rain. After you are done spraying, leave the vehicle overnight so the lubricant can soak into the rubber bushings.

6. Reassemble the wheel

After you let the rubber lubricant soak in overnight, reassemble the wheel and take your vehicle for a test drive. At this point, you shouldn’t hear any squeaking or creaking noises coming from the suspension while driving over a bump or rocking your car.

When To Change Bushings In Car

- When you hear squeaking or creaking noise coming from the suspension, that is a clear sign that the bushings are old and have started to fail. It is only a matter of time before you start hearing clunking noises.

- If the bushings are bad you will hear clunking noises. This happens when you start driving and the wheel will shock backward causing a clunking noise.

- The best way to tell if your bushings are bad is to jack up your car and perform some tests. Grab the tire by the nine and three clock position and try to move the wheel back and forth. There should be no motion. If there is a movement, you need to replace your bushings.

What Causes a Squeaky Suspension

-orn-out or damaged suspension components such as bushings, control arms, or ball joints.

- Lack of lubrication on suspension parts.

- Loose or worn-out strut mounts.

- Insufficient or worn-out shock absorbers.

- Corrosion or rust on suspension components.

- Misaligned or improperly installed suspension parts.

- Overloading the vehicle beyond its recommended capacity.

- Driving on rough or uneven surfaces.

- Extreme temperature changes affect the suspension components.

Signs of Squeaky Suspension

- Squeaking or creaking noises coming from the suspension while driving over bumps or uneven roads.

- Excessive bouncing or bouncing that doesn’t quickly settle after hitting a bump.

- Uneven tire wear or abnormal tire wear patterns.

- Poor handling and stability, including drifting or pulling to one side.

- Increased body roll or leaning during turns.

- Vibrations or shuddering felt through the steering wheel or vehicle body.

- Difficulty in maintaining control of the vehicle, especially on rough roads.

- Visible signs of damage or wear on suspension components such as cracks, tears, or leaks.

- Changes in the vehicle’s ride height, including sagging or uneven suspension.

Is Squeaky Suspension Dangerous?

A squeaky suspension in a car is generally not considered life-threatening or dangerous. However, it indicates an underlying issue with the suspension system that requires attention.

The squeaking noise is often a result of dry rubber bushings or worn-out components.

While it may not pose an immediate risk, driving with a squeaky suspension can lead to further damage and potentially unsafe conditions .

FAQs

Q: What causes a suspension to squeak?

A: A suspension can squeak due to various reasons. The most common cause is a lack of lubrication. When the suspension components rub against each other without proper lubrication, it can result in squeaking. Additionally, worn-out bushings, ball joints, or struts can also contribute to the squeaking noise.

Q: How much does it cost to fix a squeaky suspension?

A: The cost of fixing a squeaky suspension can vary depending on the specific issue and the vehicle. If it is a simple lubrication problem, it may only cost a few dollars for a can of lubricant. However, if there are worn-out parts that need to be replaced, the cost can range from a few hundred to a few thousand dollars.

Q: Can I lubricate the suspension myself?

A: Yes, you can lubricate the suspension yourself if you have the necessary tools and knowledge. However, if you are not confident in your abilities or if the issue seems more complex, it is recommended to consult a professional mechanic.

Q: What lubricant should I use to fix a squeaky suspension?

A: There are various lubricants that can be used to fix a squeaky suspension. Popular options include grease, silicone spray, or specific suspension lubricants. It is important to choose a lubricant that is compatible with the suspension components and follow the manufacturer’s instructions.

Q: How often should I lubricate my suspension?

A: The frequency of lubricating your suspension depends on various factors such as the type of vehicle, road conditions, and driving habits. Generally, it is recommended to inspect and lubricate the suspension components every 12,000 to 15,000 miles or as recommended by the vehicle’s manufacturer.

Q: Can a squeaky suspension affect the performance of my car?

A: Yes, a squeaky suspension can affect the performance of your car. In addition to being annoying, it can indicate underlying issues such as worn-out parts or inadequate lubrication. These issues can lead to decreased stability, increased tire wear, poor handling, and potentially compromise the overall safety of your vehicle.

Q: How do I identify which suspension component is causing the squeak?

A: Identifying the specific suspension component causing the squeak can be a bit tricky. It often requires a thorough inspection and, in some cases, a test drive to isolate the noise. If you are unsure, it is best to consult a professional mechanic who can diagnose the issue accurately.

Q: Can I use WD-40 to fix a squeaky suspension?

A: Using WD-40 can be a temporary solution to fix a squeaky suspension. It can help lubricate the components and reduce the squeaking noise. However, WD-40 is not a long-term solution for suspension lubrication and should be used cautiously. It is recommended to use a proper suspension lubricant for a more effective and durable fix.

Q: What should I do if my suspension still squeaks after lubrication?

A: If your suspension continues to squeak even after lubrication, it may indicate a more underlying issue such as worn-out parts or damaged components. In such cases, it is best to have your suspension professionally inspected and repaired by a qualified mechanic.

In Conclusion

The steps to fix a squeaky suspension may seem intimidating at first, but with the right tools and technique, it can be done quickly and easily.

There are many different techniques for fixing a squeaky suspension, ranging from simple lubrication of the springs to more complicated repairs or replacements.